Electrode wire

SAW and SPB brass wire performing all-around capability,

and SUB ultimate brass wire pursued the best quality, SPW+E coated wire enable to expand productivity massively,

you can select best appropriate wire according to your machining requirement.

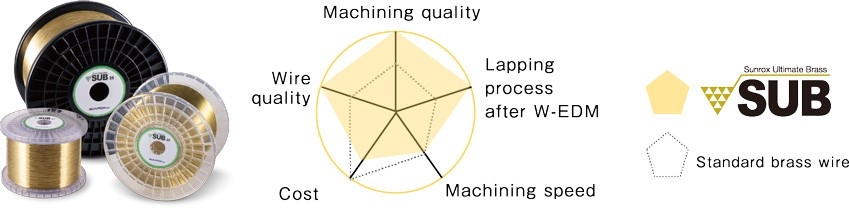

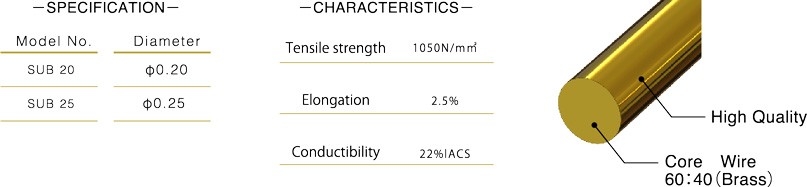

SUB SUNROX Ultimate Brass

High end model implementing high accuracy!

High end model implementing high accuracy!

Ultimate brass wire fullfills requirement for high product quality

Product features

Product characteristics

-

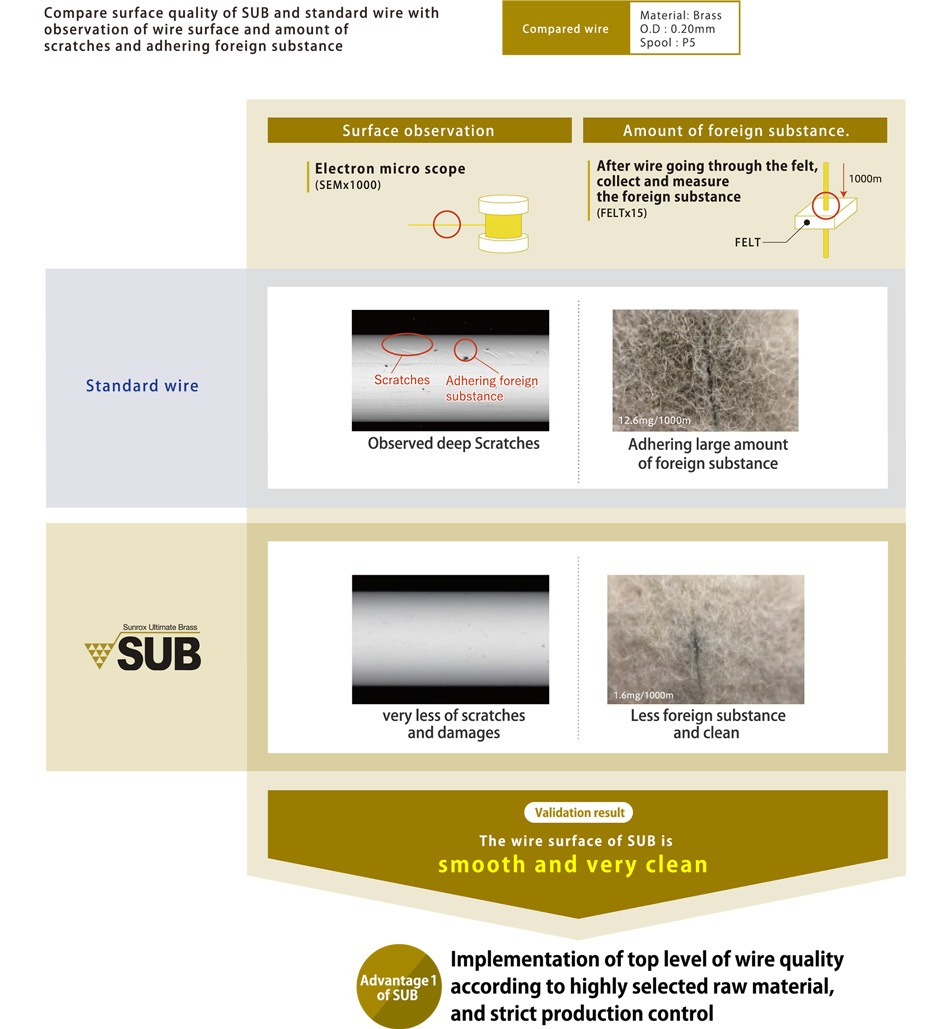

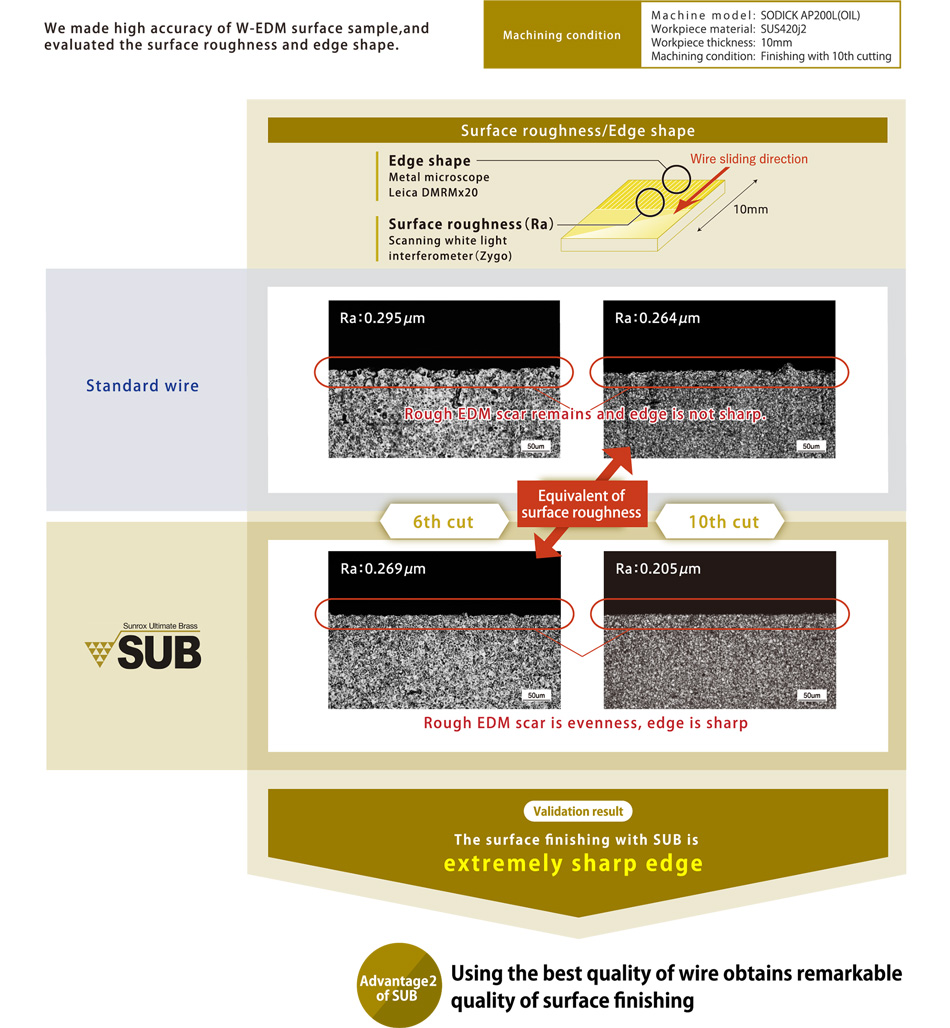

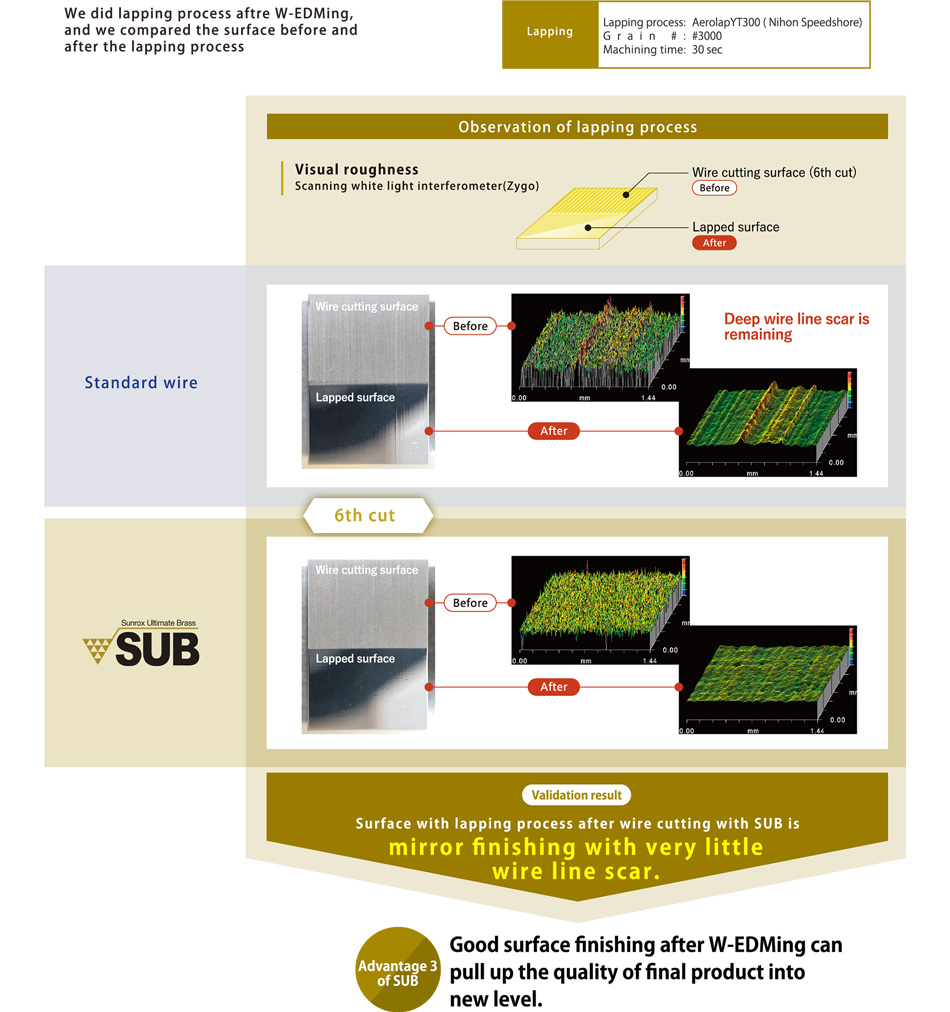

Implementation of the best quality of brass wire

-

obtains remarkable quality of surface finishing.

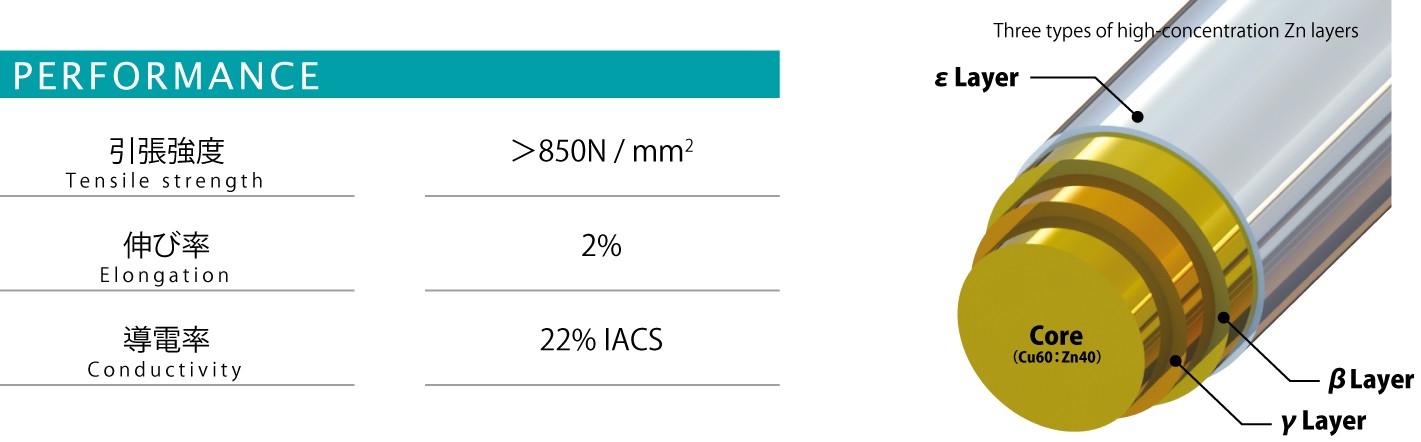

SPW+E SUNROX Premium Coating Wire Plus Epsilon

Three-layer structure using new technology.

Coated wire that combines speed and precision will become the standard from now on.

Product characteristics

Cutting characteristics

-

Multi coating layer is better suited for high speed machining.

-

Keep good surface finishing even though machining speed increases.

Cost・Profit simulation

-

Get more profit with cost-cutting + more productivity.

-

We prepare “Simulator” to estimate the Cost & Profits

Reflecting user’s actual cutting condition

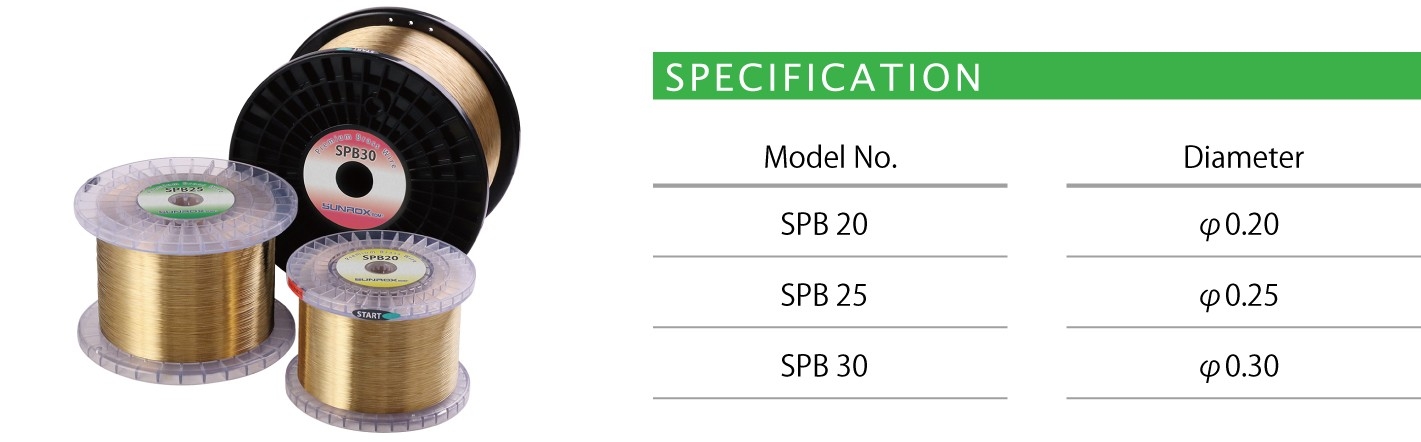

SPB SUNROX Premium Brass Wire

SPB is all-round brass wire suitable for any brands of W-EDM.

Sunrox Original Wire

SPB is SUNROX original brass wire for W-EDM.

Stable performance

We control selected material and machining process, so you can use SPB with stable performance!

High reliability for Auto Wire Threading

SPB is quite reliable for Auto Wire Threading System because of well streightness.

Save cost

Since the price is much reasonable than before, it must contribute the reduction of your cost!

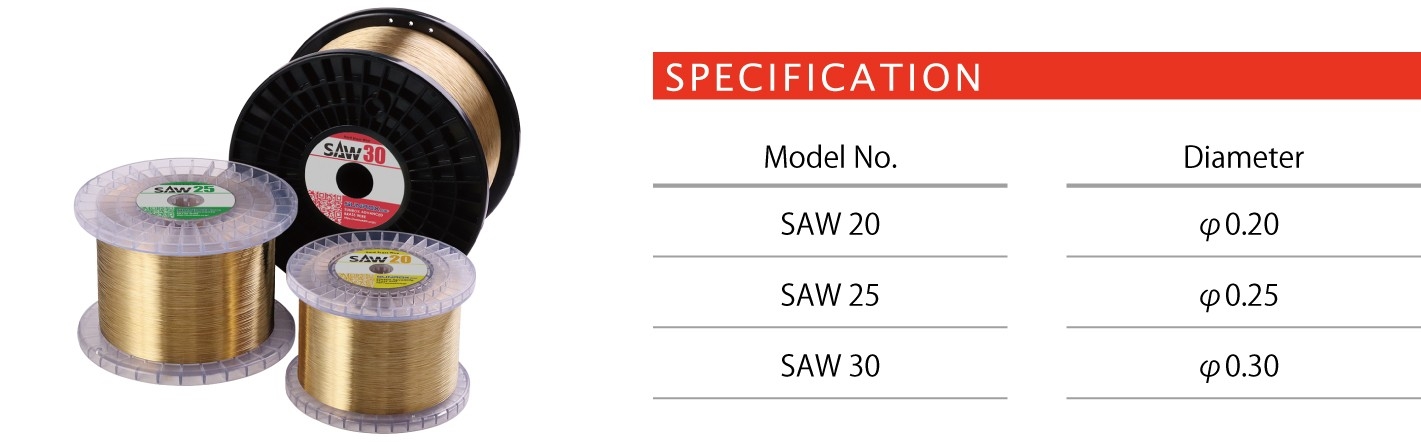

SAW SUNROX Advanced Brass Wire

SAW is all-round brass wire suitable for any brands of W-EDM.

Sunrox Original Wire

SAW is SUNROX original brass wire for W-EDM.

High reliability for Auto Wire Threading

SAW is quite reliable for Auto Wire Threading System because of well streightness.

Stable performance

We control selected material and machining process, so you can use SAW with stable performance!

Save cost

Since the price is much reasonable than before, it must contribute the reduction of your cost!

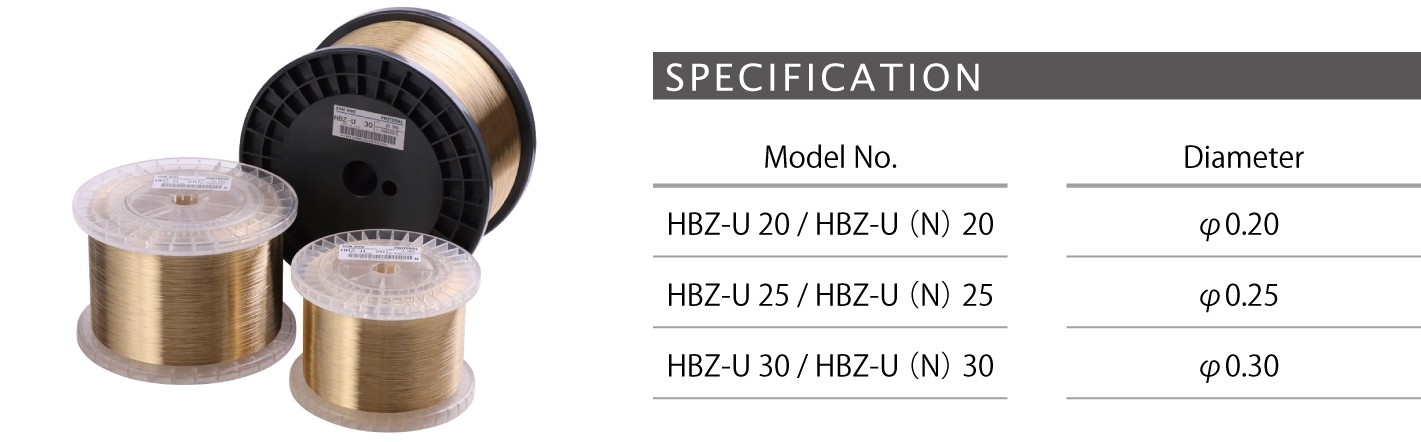

PROTERIAL HBZ-U WIRE

BZ-U is a wire specially developed for automatic connection, based on PROTERIAL’s plastic processing technology.

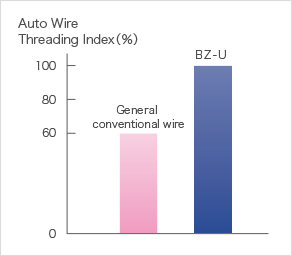

High Auto Wire Threading Rate

High AWT(Auto Wire Threading) rate Since toughness of wire is large, get great straightness, you can get Improvement of AWT rate even in the type of AWT system such as pipe way, jet-cut way, anneal cutting way of W-EDM.

Best suited composition

Minimize impurities such as Pb(lead) which drop the performance of wire, on the other hand, we use selected materials carefully to have good electric discharge characteristic.

High dimensional accuracy

We use diamond drawing dies which are controlling diameter strictly, we control the tolerance of Wire diameter ±1μm and roundness within 1μm.

Consistent mechanical feature

Both hard material (H), soft material (A) are well controlled under consistent figure on the spec of tensile strength and other specs.

High surface quality

No scratches and no dents on wire surface and it is extremely smooth. In order not to have brass powder, we do special original surface treatment on the wire.

High machining speed

We focus attention on Zn(Zinc) to improve cutting speed, and we could see improvement of cutting speed on the same application and condition because of best suited composition.

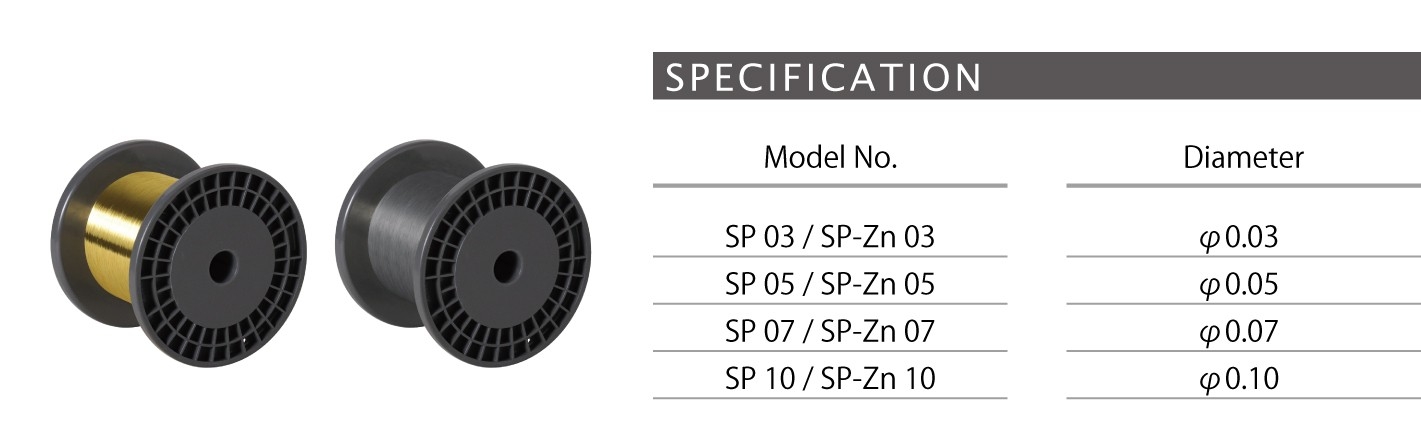

SP WIRE / SP-Zn WIRE

SP/SP-Zn wire is excellent EDM wire in strength and straightness, especially for high precision machining.

Characteristic of SP Wire

High Tensile Strength EDM wire

SP wire has high tensile strength and provides excellent processing precision as the uniformity of the wire diameter allows for high-speed processing. Moreover the surface roughness is satisfactory.

Low-Cost, High Performance Electrode Wire

SP wire is a low-cost wire electrode for precision processing which features higher tensile characteristics as compared to tungsuten and molybdenum, as well as possessing a processing performance close to that of brass wire.

Excellent Surface Characteristic

SP wire provides good results with respect to wear on currentcarrying pins as well as on the various guides of the wire running system as the wire surface is plated with brass.

Excellent straightness

Straightness is fully taken into consideration at the manufacturing stage of SP wire. It is accomplished by means of precision fine processing and automatic connection.

Characteristic of SP-Zn Wire

SP-Zn wire is Electrode wire for Super precision Electric discharge machine. SP-Zn Wire offers a stable electric discharge characteristic and high processing speed by the zinc of the outer layer. SP-Zn wire has high tensile strength and excellent straightness the same as SP wire.